Aluminum in its purest form is not found naturally and we only began to discover it about 200 years ago. People first figured out how to make aluminum with electricity in 1886. We still use this method.

Aluminum is a metal that can be found in the Earth’s crust. It is the third most common element, with oxygen and silicon being the most common. It makes up more than 8% of the Earth’s crust.

Aluminum History

People have been making aluminum for a long time. They used to use something called Alum, which is a special kind of salt made from aluminum, to make leather and paper resistant to fire. But people only found out about the aluminum we use today in the 1800s.

A long time ago, a scientist named Humphery Davy said that aluminum could be made by using electricity on a certain substance, but he didn’t have the things he needed to try it out. In 1825, Hans Christian Oersted made a metal called aluminum using Davy’s thoughts.

Napoleon III was a person who lived a lot of years ago. Assisted in making aluminum in France. Nowadays, aluminum is commonly used for many things because it is lightweight and does not easily rust.

Karl Josef Bayer found another way to make aluminum in 1888. The Bayer process makes aluminum by heating bauxite and an alkali mixture.

Steps For Making Aluminum

- Bauxite Mining

- Crushing

- Digestion

- Precipitation

- Aluminum Production

- Electrolytic Reduction

- Reduction Process

- Casting

- Primary Aluminum

- Foundry Alloys

- Rolling

- Extrusion

- Aluminum Alloys

- Recycling

Bauxite Mining:

Karl Josef Bayer found another way to make aluminum in 1888. The Bayer process makes aluminum by heating bauxite and an alkali mixture.

Bauxite is a type of rock that has a material called alumina inside of it. People make things with alumina. Alumina has damp things in it called hydrated aluminum and aluminosilicates. This thing has different types of metals and types of sand called silica. There are many kinds of rocks like gibbsite, boehmite, hematite, and more.

Bauxite is a kind of rock that is formed when smaller rocks are broken down by the weather. We can find them in different rocks like ones that have changed shape from heat and pressure, ones that have formed from layers of sediment, and ones that have formed from cooled magma. The big stones we mentioned before have been affected by weather for millions of years.

90% of the world’s bauxite is found in hot areas. The ground far away from here has been eroded for a long time.

The biggest places where we find bauxite are in Central and South America, West Africa, India, Vietnam, Australia, and especially Guinea. More water storage places can be found in the north of Russia and the middle of Saudi Arabia. Bauxite is often found in places close to the top layer of the earth.

Bauxite is usually not found underground and is covered by rocks, but sometimes it can happen. We have found over 70 billion tons of bauxite all over the world. Guinea has a lot of bauxite, which is used to make aluminum. There are a lot of it, about 25 billion tons, in that area.

There are rocks and minerals found underground, but sometimes they are also found on the surface. When they are on the surface, they can be easy to access. However, sometimes they are deep underground and need to be mined to be used economically. This happens a lot with certain places to store things in Russia.

Mining surface deposits involves these steps:

-Using large machinery, such as bulldozers and scrapers, to remove plants and extract the valuable soil on top.

-Removing the upper layer of dirt and stones.

-Getting metal from the ground needs strong tools or explosions to remove it from difficult places. The idea is to make holes and put bombs in some places, or use big machines to create an opening.

-Putting things on trucks and taking them to a location to break them down into smaller parts. Mines have trucks of different sizes, some are small and carry 30 tons while others are bigger and can carry 180 tons.

-Moving things to sell in other countries or to make other things in the same country.

Every year, people dig up around 165 million tons of bauxite from the earth. Bauxite is transported to factories by belts, trains, or boats. Some factories that make alumina are built near the places where they get the raw material, called bauxite. The places where people take out bauxite often have between 500 and 1000 workers.

Crushing And Digestion

The rocks are put in big containers with a special liquid called caustic soda and they heat it.

When caustic soda mixes with aluminum compounds in bauxite, it produces a substance called sodium aluminate. Another word for this is slurry. The unwanted parts, called red mud, with iron, silicon, and titanium in them, are removed from the bottom of the tank.

Rolling

The metal called aluminum is made into long bars that are shaped like rectangles, and they can be as long as 9 meters. The bendable aluminum bars can be flattened into thin pieces. This thing is good for making cans and flat pieces. It can be made thin and flat, just 0. 006

Extrusion

This is a common way to make a fixed profile. The metal is heated and then forced through a machine using a lot of pressure. After the material is made, it is cooled down and pulled to make sure it’s not under too much pressure. This flexible method is used to make a lot of BA Systems balustrade items, such as the B40 Frameless Balustrade base ICE channel. Please provide the text to be rewritten in simple words.

Aluminum Production

Bauxite is crushed into small pieces, dried, and made into powder using special machines. After that, a small amount of water is poured into it. We create a thick mixture and place it in special containers. We use steam to remove a lot of the silicon from the bauxites by heating them.

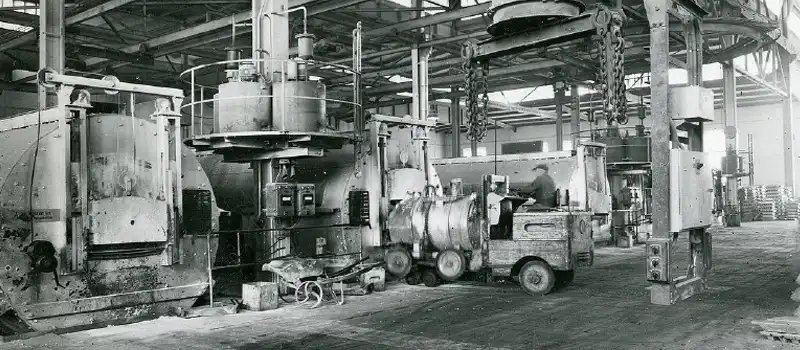

Reduction Process

At an aluminum factory, alumina is fixed with melted cryolite at a very high temperature. Electricity is passed through a mixture and it makes the aluminum separate from the oxygen, causing it to become liquid and settle at the bottom. This happens when the electricity reaches 400,000 amps or more.

Primary Aluminum

First, they make primary aluminum. Then, they put it into ingots and send it to customers. Or, they use it to make different kinds of aluminum for different uses.

Aluminum Alloys

The alloy is created when we melt aluminum and mix it with other stuff. After getting colder, the mixture becomes a solid and is the same all the way through. Some additional objects can make up 15% of the total weight of the metal mixture. Some new things are added. They are iron, copper, magnesium, silicon, and zinc. When we put extra things in aluminum, it becomes stronger and can carry electricity better. It doesn’t rust easily. This mixture is called an alloy. Aluminum blends are light and not easily affected by rust.

Recycling

When we reuse old aluminum, it saves more energy than making new aluminum. Just 5% of the energy is required. Aluminum can be recycled multiple times without losing its original qualities.

Recycling aluminum is when we take aluminum that has already been used and make it clean again so we can use it again. The shiny aluminum is heated up until it turns into liquid. The melted aluminum is turned into big blocks that can be shaped or flattened.

Aluminum does not rust like iron. This means we can melt it and use it again many times. As we mentioned, recycling aluminum is easier and needs less energy than making new aluminum.